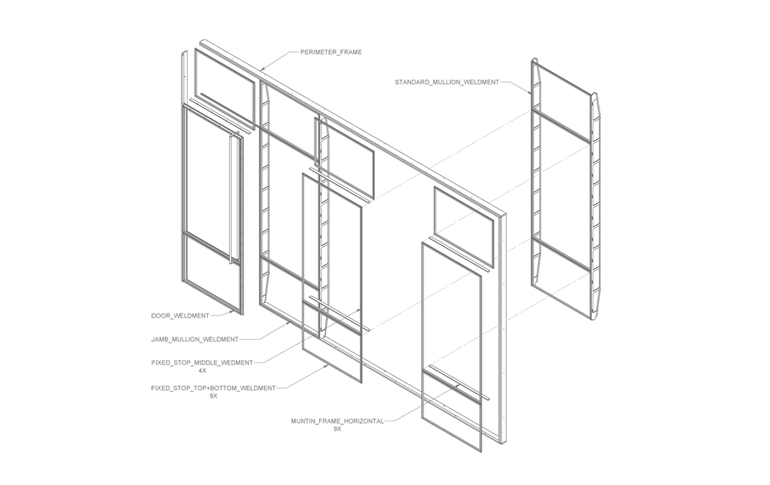

Caliper has developed and refined the details for several building component types including: a steel and glass interior door system, a steel and glass skylight system, and an adjustable shelving system. Designed to be ordered to custom specifications on a per project basis, the systems provide a level of functionality and efficiency closer to a developed product than a one-off custom solution.

A well designed, well constructed building keeps out water and wind, is smart about its orientation and exposures to let in sun energy when desired and keep it out when not. Well designed buildings get the insulation on the right side of the air and vapor control layers to prevent mold growth and have windows and doors that seal tight. When buildings are tight they need continuous fresh air delivered to every room and this air can be filtered and can be pre-heated by the outgoing exhaust air in the winter to save energy and eliminate drafts. If a building is designed with performance in mind it costs less to operate by using less energy and often needs less mechanical equipment which can reduce its cost to build. Most importantly a building designed with performance in mind is more comfortable and provides its owners and occupants with the satisfaction of living in a well designed environment. Caliper continues to explore smarter construction methods and to develop custom tools to help us understand how design decisions affect performance before they get built.

Using mechanics in building components allows for the transformation of space as well as the opportunity for increased building performance. Programmatic requirements and compact spaces create the opportunity for adaptable rooms through operable partitions or large scale door systems, and Caliper is interested in developing new mechanics and systems that make it possible for these to adapt to varying circumstances. Caliper is also interested in the potential of automated operable windows as a means to capitalize on temperature fluctuations to efficiently moderate and maintain comfortable internal temperatures.

As a firm with a hands-on approach to the physical construction of buildings, Caliper is particularly interested in exploring the potential of alternative methods of construction. Caliper has worked with sprayed cementitious wall systems on two projects and continues to explore innovative uses of CNC cut pipe as self-jigging framing members.

Caliper continues to explore the use of custom software tools to assist in the design process. Custom scripts can iteratively explore a range of possible solutions that meet stated design criteria, and can help manage the flow of information in particularly complex design solutions. Coupled with tangible goals and a deep understanding of physical fabrication methods these tools are a powerful complement to intuition and experience.

Caliper looks for opportunities to explore the fabrication of complex geometry through simple fabrication methods. One example is a bent metal rain screen panel system constructed of sheet metal with different sized notches removed from each corner and the edges folded to form a standoff and attachment flange. The result is irregular three dimensional panels that create an effect similar to wind rippled water. Metal panel rain screen facades are ideal cladding systems for high performance buildings with exterior insulation and the potential for unique patterns through bending and cutting provides fertile ground for exploration.